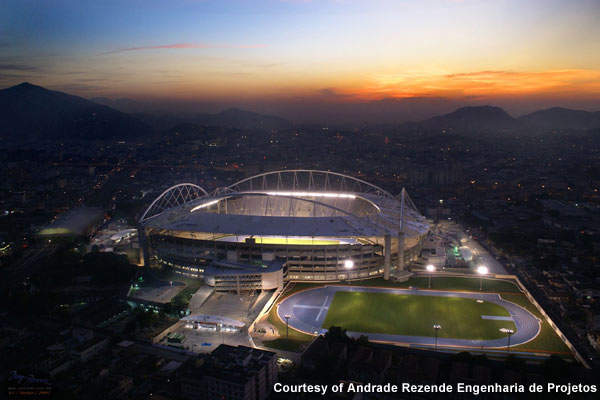

Located in the Engenho de Dentro neighbourhood of Rio de Janeiro, the João Havelange Olympic Stadium (Estádio Olímpico João Havelange) is an iconic multi-use stadium in Brazil. Also known as Engenhão, João Havelange is one of the most impressive stadiums in South America. Built with an initial seating capacity of 45,000, it is mainly used for football games and athletics, and has a football field and two athletics tracks in an area of 21 acres.

The João Havelange Olympic Stadium was designed by architects Carlos Porto, Gilson Santos, Geraldo Lopes and José R. Ferreira Gomes. The stadium is named after João Havelange, the Brazilian ex-FIFA president from 1974 to 1998.

The stadium, which is owned by the city of Rio de Janeiro, has been rented to Botafogo de Futebol e Regatas for a 20-year period (from August 2007 to 2027) and is the home field of the Botafogo soccer team.

Construction of the stadium began in September 2003 and was completed in June 2007. On 30 June 2007 it officially opened to host the XV Pan American Games. The cost of the stadium’s construction was estimated at $30m in 2003 but ultimately raised to $192m due to construction delays.

On 2 October 2009 the International Olympic Committee selected Rio de Janeiro to host the 2016 Summer Olympic Games, for which the João Havelange Olympic Stadium will hold athletics competitions.

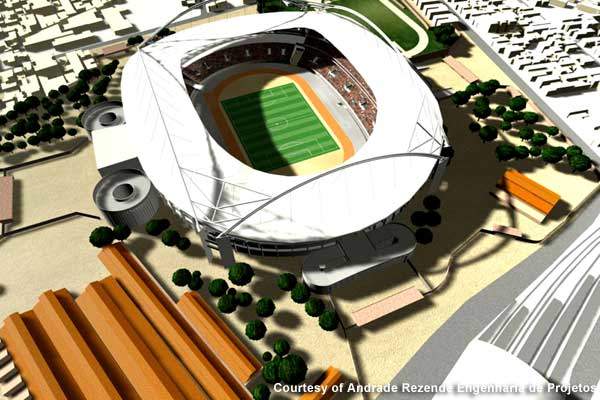

In preparation for the games, the stadium’s seating capacity will be increased by 15,000 to accommodate up to 60,000 guests. The areas surrounding the stadium will also be renewed as part of a long-term development project.

João Havelange Olympic Stadium design

The João Havelange Olympic Stadium has an oval-shaped structure with axes measuring 284m and 232m, and large openings.

The stadium is covered by a huge metallic suspended roof with an airy design, which is supported by white steel arches – designed in a rhythmic repetition of irregular forms – and cable-stayed strings. The design of the roof makes it look as if it is floating in mid-air.

The roof of the stadium has an environmentally sustainable design, which captures rainfall to water the grass field.

Svelte concrete structures support spectator transit areas and the stands.

Olympic stadium structure

The 3,300t stadium roof is suspended by stretching on a set of four complex arches, which are built to support the floating roof. The opposite sizes of the arches measure 180m and 220m. The tubular steel arch structures are built in the east and west sections at heights of 73m and 64m respectively, and are 2m in diameter.

Covering the entire seating area of the stadium, the roof with its projection and extensions has a coverage area of 34,250m². The stadium has four sectors that are accessible by four independent ramp sets. The deck of the stadium is composed of more than 60,000 unique pieces, which were stabilised after the assembling completion.

João Havelange stadium construction

The construction of the stadium’s structure, roof and additional services involved a combination of creativity, technological innovation and modern construction techniques.

Construction was accomplished in two stages: the first stage involved the cover construction and the second, the assembly.

The design of the floating roof was most challenging, for which temporary support structures were specifically built.

The stadium required around 40,000m³ of concrete pour, an estimated 35,000m² of steel structure for the coverage and 2,700t of steel for construction. Approximately 1,600 direct and 1,500 indirect jobs were generated during the project’s construction.

Brazilian Olympic stadium facilities

Facilities at the stadium meet stringent international regulation standards in terms of comfort and safety. Seats are numbered and made of fibreglass for the comfort of the audience.

The João Havelange Olympic Stadium has 98 spectator cabins (ranging from 30m² to 60m²), 60 radio and TV booths in eight sections, as well as two electronic scoreboards and two large screens.

Encompassing a technical area, warehouse and five locker rooms, the stadium has areas for medical care and a front desk. It also has a shopping area and separate stores for the sale of sports material, covering an area of three million square feet. In addition, the stadium has space for leisure facilities, restaurants, 24 bars and 67 bathrooms.

Contractors

The Racional, Delta and Recoma consortium was contracted by the municipality of Rio de Janeiro contracted for the building of the stadium’s basic structure. Infrastructure facilities, including the tiled roof, air-conditioning and automation systems, were contracted with OAS, CVS and Norberto Odebrecht consortium.

The engineering of the steel structure was carried out by a number of different companies. The basic metallic casing structures were contracted with Project Alpha Company, while executive project engineering was provided by Andrade Rezende. TAL Project supplied the consulting and verification.

The fabricated rebar and reinforcing steel mesh was provided by Gerdau, with steel coverage supplied by Perfilor and thermal insulation from Firestone. Indutech and Assembly Industrial Ltda provided the manufacturing of the arches chisel.

DW Engenharia was responsible for the mechanical exhaustion and air-conditioning; MBM Engenharia was involved in the building installations. Visual communication equipment was supplied by Modonovo and Bruno Porto.