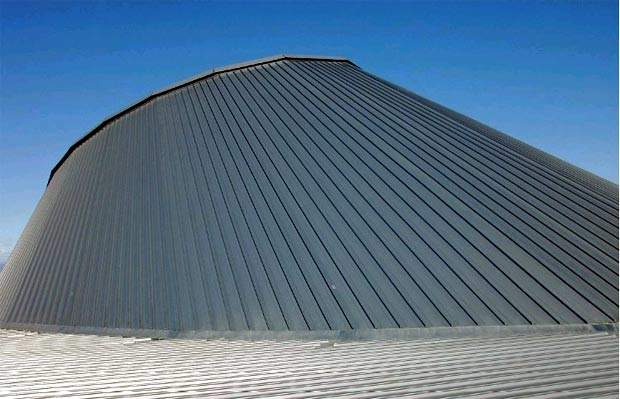

The Milan Exhibition Centre has been noted for its innovative use of roof and skylight construction. Using advanced Monro profile techniques, it has broken new ground.

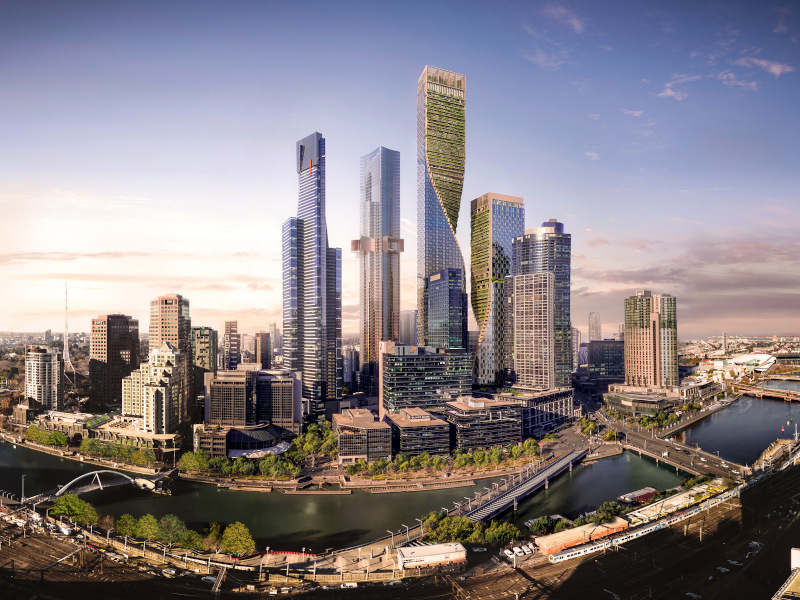

Of the eight pavilions of the Milan Exhibition Centre, two are two-level, four are single-level and two higher-than-standard. All are keynoted by distinctive features, such as the tubular skylights that dot the skyline around the new complex.

Profile Engineers were the turnkey solution partner in this project for the roof and skylight construction. Extensive tests for wind load, waterproofing, static and acoustic were defined and successfully executed by them to guarantee all the

requirements of the public authorities and the client.

MONRO PROFILES

Both conventional profiles and new Monro profiles were used in Milan. The Monro profile is a conical standing seam profile that can also be supplied with rounded edges if needed and which can be shaped to suit customer needs.

The engineering firm who worked on this project are currently the only company worldwide that can supply a product of this type, which offers a nearly unlimited range of design variations.

The engineers developed a new roll-former for the Monro standing seam profile. The new machine cuts and forms metal sheets from 0.7mm to 1.2mm thick, producing finished profiles of any length in a single pass.

REVOLUTIONARY ROOF DESIGN

Profile sheets made by this method have revolutionised the design of roofs and structures based on industrial standing seam profiles because it is only thanks to this technology that such complex shapes are at all possible.

To enable the machine to work with maximum flexibility, the on-site engineering team also developed a special software package called ‘X-Form’. With this software the user can define sheets on the basis of a 3D model and send the design data directly

to the former by modem.