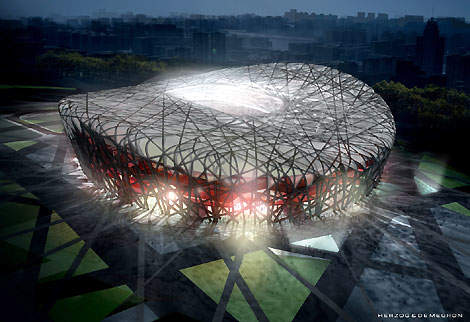

Built at a cost of £300m, the Beijing National Stadium, located at the south of the centrepiece Olympic Green, is a stunning landmark building that staged the 2008 Olympic Games from 8 August to 24 August 2008. The opening and closing ceremonies and athletic track and field events of the 29th Olympiad took place at the stadium. It also hosted the Summer Paralympics from 6 September to 17 September 2008 and Race of Champions 2009.

Beijing National Stadium will host the opening and closing ceremonies of the 2022 Winter Olympic Games making Beijing the first city to have hosted both Summer and Winter Olympics.

A gross volume of three million cubic metres made it the world’s largest enclosed space at that time. It was then also the world’s largest steel structure with 26km of unwrapped steel used.

The innovative structure was designed by Herzog & De Meuron Architekten, Arup Sport and the China Architecture Design and Research Group, and has been nicknamed the “bird’s nest” due to the web of twisting steel sections that form the roof.

As well as designing a modern stadium, the team was challenged with creating a venue that was part of the culture of China and would put Beijing on the map.

The 91,000-seat stadium was designed to incorporate elements of Chinese art and culture. The National Stadium’s main structure is an enormous saddle-shaped elliptic steel structure weighing 42,000t. The stadium extends 333m from north to south and 294m from east to west, with a height of 69.2m. The stadium design included demountable seats of 11,000.

Beijing National Stadium structure and design

The stadium has two independent structures, a red concrete seating bowl and the outer steel frame around it at a 50ft distance. As this was an Olympic venue, there were many standards that the design consortium had to conform to. Everything from the width of the track to the size and location of the long and high jump pits needed to satisfy the requirements set out by the International Olympic Committee (IOC) and the International Amateur Athletics Federation (IAAF).

The architects and engineers also had to satisfy the requirements laid down by the National Stadium Company in order to create a bold, stand-out, world-class stadium and to design it with as much flexibility as possible for future use.

When you play in anbest online casinos canadain a stadium, you get a payout of 6 to 5 instead of 3 to 2. This is an unusual feature of online casinos. While most online casinos in Beijing National Stadium, ‘The Bird’s Nest’ may offer a stadium game. For example, a stadium has 44 online casino seats. In addition, the stadium casino table is customizable and allows players to decide what type of casino they would like to play.

The circular shape of the Beijing Olympic stadium represents heaven, but has been described as a bird’s nest, with its pattern inspired by Chinese-style crazed pottery. A series of cantilevered trusses has been designed to support the roof, shading the seats. While designing the national stadium, architects and engineers also ensured comfortable seats and optimum view for all spectators.

Focus was also given to designing the Beijing stadium in such a way that it should be able to withstand earthquakes without much damage as the stadium is located in one of the world’s most seismic zones.

The concourses are wide and spacious for making the refreshment and merchandising stalls easily accessible. There is also a large mixed-use retail development beneath the stadium featuring shops, restaurants, cinemas, a health club and parking.

The football field of the stadium with an area of 8,000m² provided enough space for the underground pipes of the geothermal heat pump (GHP) system, through which ground-source energy is collected. In winter, the system absorbs the heat from the soil and helps heating the stadium, while in summer the coldness from the soil is stored which cools the stadium.

Computational fluid dynamics (CDF) simulation based on the Games-time situation has been used to calculate the temperature and airflow speed at each angle of the structure and optimise all ventilation facilities accordingly.

Financing for the Beijing stadium

The China International Trust and Investment Corporation (CITIC) consortium, which raised 42% of the finance for the project in return for a 35-year tender after the Olympics were finished, comprises the CITIC Group, the Beijing Urban Construction Group, the Golden State Holding Group of the United States, and the CITIC Group affiliate Guoan Elstrong (a public, private partnership arrangement).

The remaining 58% is funded by the Beijing Municipal Government and this has been entrusted to the Beijing State-owned Assets Management Co Ltd as the city government’s representative.

Beijing Stadium contractors and construction

Construction of the Beijing stadium began on 23 December 2003 and was finished in early 2008. Beijing Mechanical Construction Company won the bid for earthwork and foundation treatment in November 2003 and work began almost immediately. CITIC Internationals Contracting Inc was the major construction contractor.

Structural engineering, mechanical and electrical engineering, fire safety engineering, acoustic design were the responsibility of Ove Arup & Partners. Beijing Urban Construction Group Co. Ltd (BUCG) organised the project along with China Architecture Design & Research Group.

To minimise the formwork construction on the bowl, the design team used precast concrete. A terrace of L-shaped precast units spanning areas between the supporting reinforced concrete in situ beams will make up the section of the middle and upper tiers. The Beijing Olympic stadium is supported by 24 main columns of 1,000t each, far more than the weight of those in a conventional stadium and spaced in what appears to be a random pattern.

The 3D steel roof spans a 330m-long by 220m-wide space. The geometry of the roof was worked out from a base ellipse of which the major axis measures 313m and the minor axis measures 266m. The façade’s external surface has an inclination of approximately 13° to the vertical. As China is highly vulnerable to earthquakes, the roof was separated from the seating bowl to help make the structure earthquake resistant.

National Stadium ‘Bird’s Nest’ architecture

The team wanted an optimum balance between making sure every spectator had a good view, creating a good atmosphere and designing an elegant building. It also needed to be aware of the different uses of the stadium; for example, when used as an athletics stadium, the most important view is at the finish line of the running track but when used for football, the best views are at the centre line.

Getting everyone close enough in such a big venue was a real challenge and getting the calculations right was an immense task. For example, changing the height of the first row of seating by just 100mm would make the stadium significantly larger and higher and increase the cost by several million pounds.

To achieve the optimum design, the team relied heavily on parametric design software. This helped to work out the sightlines, the bowl geometry, airflow to keep the grass in good condition, seismic studies and the design of the external envelope.

While the surface of the structure is simple, the geometry is complex – the calculations were so numerous and complicated that they could not be solved manually. Software was needed to make sure that the web of twisting steel sections fitted together, as they have to twist and bend to follow the surface accurately.

The main elements support each other and converge into a grid formation. The stand of the national stadium is a seven-storey shear wall system with a concrete framework. The upper part of the stand and the stadium steel structure are actually separated from one another, but both of these are based on a joint foundation.

The “nest” structure, however random it might look, follows the rules of geometry and contains 36km of unwrapped steel. The shape of the roof was inspired by yin yang, the Chinese philosophy of balance and harmony.

The roof is covered with a double-layer membrane structure, with a transparent ETFE (ethylene tetrafluoroethylene) membrane fixed on the upper part of the roofing structure and a translucent PTFE (polytetrafluoroethylene) membrane fixed on its lower part. A PTFE acoustic ceiling is also attached to the side walls of the inner ring.

The spaces in the structure of the Beijing Olympic stadium are filled with inflated ETFE cushions. On the façade, the inflated cushions are mounted on the inside of the structure where necessary, to provide wind protection.

Since all of the facilities – restaurants, suites, shops and restrooms – are all self-contained units, it is possible to do largely without a solid, enclosed façade. This allows natural ventilation of the national stadium, which is the most important aspect of the stadium’s sustainable design.

To keep costs down, all the structural elements of the stadium are contained within it, so there are no towers or cable nets. The bowl of the structure is split into eight zones, each with its own stability system, making each zone effectively as its own building.

Entrance to the Bird’s Nest stadium is controlled by tripod barriers supplied and fabricated by Kaba Gallenschütz of Germany. The project involved the installation of 138 of these units at the 12 entrances to the stadium.