The Beijing National Aquatics Center, also known as the Water Cube, is an aquatics centre built alongside the Beijing National Stadium used for swimming competitions of the 2008 Summer Olympics.

In July 2003, Australian-based architects PTW and engineering company Arup won the contract to design and build the centre.

The 80,000m² site is situated opposite the main stadium in the Olympic Green Precinct, which lies at the northernmost end of Beijing’s north-south axis. It holds 6,000 permanent seats with a capacity for an additional 11,000 temporary seats to accommodate Olympic spectators.

Construction of the $140m landmark project began in December 2003 and was completed in January 2008.

Water Cube design details

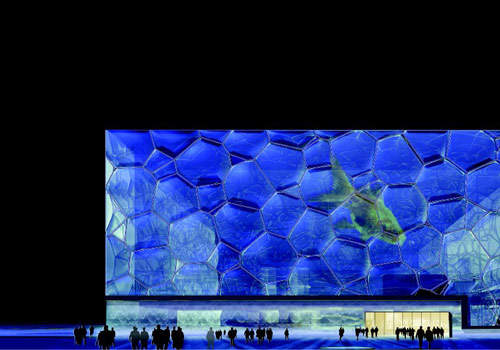

The design of the project associates water, as a structural and thematic leitmotiv, with the square, which is important in Chinese tradition and mythology. In the daytime, the Water Cube shines as a blue transparent spectacle while after sunset it is a crystal piece of architecture with LED-lit bubbles.

Conceptually the square box and the interior spaces are carved out of an undefined cluster of foam bubbles, symbolising a condition of nature that is transformed into a condition of culture. The overall appearance of the aquatic centre is a cube of water molecules.

The structure’s shape is specifically designed to work in harmony with the circular main Olympic stadium known as the Bird’s Nest, giving the area a visual ‘yin and yang’ balance.

The square form was also used in acknowledgement of its significance in Chinese culture, architecture and town planning.

Water Cube structure details

The structure of the building is a 3D vierendeel space frame measuring 176m x 176m x 29m. It is based on a geometric cell made up of 12 pentagons and two hexagons.

The Water Cube’s structural framework comprises two parts – internal and external.

The external structure forms the actual roof, ceiling and walls and comprises a flat web of rectangular boxed sections. These sections are clad with the inflatable material transparent ‘teflon’ material known as ethylene tetrafluoroethylene (ETFE).

The ETFE cladding allows more light and heat penetration than traditional glass, resulting in a 30% decrease in energy costs.

The internal steel frame is based on the unique geometry of biological cells or soap bubbles. The architects based the “soap bubbles” structural concept on a solution from two Irish professors of physics at Trinity College, Dublin, known as the Weaire-Phelan structure, whereby a recurring pattern of polyhedrons is packed together to occupy a three-dimensional space in the most efficient way possible.

More than 22,000 stainless steel members form the sides of these ‘bubbles’, which are welded at the joints to more than 12,000 spherical steel nodes. The benefit of this frame design, as well as resembling water bubbles, is that it is ideally suited to the seismic conditions found in Beijing.

Water Cube challenges

One of the challenges encountered by the designers was convincing Chinese authorities of the value of ETFE.

There were many myths about the use of ETFE, regarding the material growing mould and being ineffective in muting external noise, which had to be dispelled.

The material was also shown to be superior in terms of lighting and thermal efficiency and will protect the internal steel members from exposure to the harsh chlorinated aquatic environment – preventing their corrosion.

The use of ETFE is expected to help the building last for about 100 years.

The transmission of light and strength of the ETFE membrane deteriorates far less than other materials. The membrane is resistant to fire and severe heat and possesses ductility and crushing resistance. It is self-cleaning in nature as the friction coefficient of the material prevents the dust from forming a layer on the material and rain can easily clear away the dust.

The building’s envelope required 100,000m² of ETFE, making it the largest ETFE structure in the world.

The enclosed swimming gymnasium could have led to high humidity, which was addressed by the incorporation of a stringent temperature and humidity control system and a recycled hot water system.

This helps to air-condition the public area and the swimming pool. Indoor and outdoor air recycling systems, solar energy systems and deck ventilation systems maintain a comfortable climate and humidity of 50%-60% in the venue.

The designers also had to prevent dewdrops from the ceiling, which could affect the swimmers in the pool or divers on the springboard.

The ETFE and air conditioning systems have partially helped to prevent dew dropping. Moreover, the building’s air supply, return inlets and exhaust outlets improve the ventilation in the upper spaces of the building.

Sustainable features of the National Aquatics Center

Approximately 20% of the solar energy falling on the building is trapped and used to heat the swimming pools and the interior area.

The translucent and recyclable ETFE panels ensure the centre is well-lit during the day with appropriate levels of internal daylight, visual connection and visual comfort, thereby saving up to 55% on lighting energy use in the leisure pool hall.

The design of the Water Cube allows 140,000 tonnes of recycled water to be saved a year. Approximately 80% of water harvested from the roof catchment areas, pool backwash systems and overland flows is reused and recycled.

The highly efficient system is effective in the face of Beijing’s sporadic rainfall patterns and potential low water levels. It also reduces the reliance on the municipal water supply system.

The space between the air-pillow walls has been completely sealed off creating a layer of insulation. During summer, a 1 metre-high vent regulates the indoor temperature of the building through heat exchange by drawing out the inside warm air and letting in the outside cool air.

The vent is sealed off during winter maintaining the warm temperature inside the venue.

Construction

At the time of design, the highly detailed structural members were envisaged to be manufactured off-site and bolted together on-site, however, a more traditional construction approach was taken.

The roof and walls were constructed in east-west strips on site, which were then moved into position. This enabled work to proceed on the building and roof construction simultaneously while preventing the need for any cranes or scaffolding within the pool halls, which may have damaged the pool structures and finishes.

The landmark building has been used since the Olympic Games as a multi-purpose leisure and swimming centre that, as well as swimming pools, includes a gym, ice-skating facilities and a cinema.

The Water Cube hosted swimming, diving and synchronised swimming events during the Beijing Summer Olympics 2008. The Beijing Olympics saw 25 world records broken in the centre. The Water Cube hosted sound and light shows in mid-2009 and became a ballet theatre to host Swan Lake. It was closed to the public for renovations from 15 October 2009.

Contractors involved

PTW and Arup designed the Water Cube in partnership with the China State Construction Engineering Corporation (CSCEC) and the CSCEC Shenzhen Design Institute (CSCEC+DESIGN).

Beijing Pake International Engineering Consulting, a consulting company, served as the project manager for the project.

LATICRETE, a construction solutions provider, supplied tile installation materials and waterproofing membranes.

Gail Architektur-Keramik, a tiles supplier, provided tiles for the project, while Sika, a speciality chemicals company, supplied silicone sealants.

Oasys, a provider of structural simulation and visualisation software, supplied its Oasys GSA and Oasys Structural Suite software to analyse the cladding.

The ETFE used was produced by Vector-Foiltec, a ETFE systems supplier based in Germany, and Yuanda Group of Shengyang, China.

Kelso Coatings, a waterproofing solutions provider, Caleffi Hydronic Solutions, a heating, plumbing and water components supplier, are some of the other contractors involved in the project.